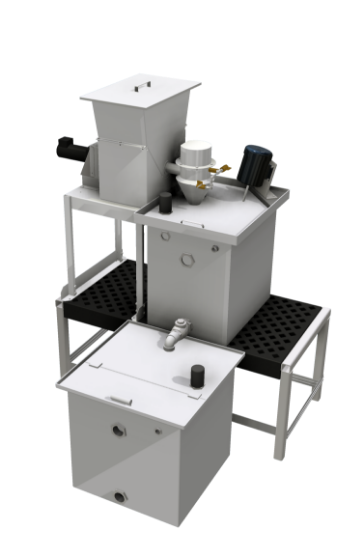

Polymer Feeder

Overview

The polymer wetting system contains everything needed to continuously wet, dissolve, and feed hydrated polymer from a variety of dry polymer styles and types. The system uses an integrated dry chemical feeder to accurately deliver polymer to a mixing cone which accomplishes initial wetting and helps prevent agglomeration. The initial solution is then dropped into a maturation tank where the polymer is properly dissolved while being mixed. Once the polymer is ready for use it is then piped into the feed tank where it will be ready to go to work.

Level sensors specifically chosen to function well while addressing the concerns typical in polymer mixing are used in both the wetting and feeding tank. The speed of the mixer motors on each tank are able to be adjusted to account for the most efficient wetting process for any particular polymer. The level sensors, valves, and motors are all tied together in a fully user configurable control unit that adjusts mix time, speed, alarms, and other user configurable parameters.

Features

- Automatic batch hydration

- Multiple tank level alarms

- 304 SS construction

- Gravity fed design

- Low maintenance

- Fully programmable

- Compatible with a wide variety of sizes and weights